Press Contact

Impressions

How do we communicate knowledge to workers?

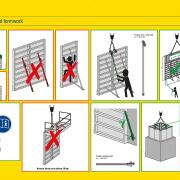

"Germany alone has around 5,000 building regulations", says Martin Sonnberger; that doesn't even include manufacturer's specifications or all the operating, assembly and usage instructions. Sonnberger, Head of Occupational Safety at the PORR construction company, is motivated by questions such as: How do we get knowledge to the construction site. And how do we get through to workers? Definitely not with ever-increasing regulations. "We are already overwhelmed by an amount of paperwork", says Sonnberger. This might be why he is full of praise for the streamlined "safety poster" approach – a Doka feature that uses short picture stories to describe the equipment needed at a construction site (e.g., formwork) and the proper way to set it up. "Simple, self-explanatory, target group-oriented and suitable for any language", says Sonnberger.Changing attitudes

This brings us to Helmut Weißengruber, responsible for Safety in Austria at theFormwork Expert Doka located in Amstetten, Austria. "The 'Safety Poster' project was developed in collaboration with customers and a neuroscientist", explains Weißengruber, because regulations alone do not alter behaviour. Workers see images of individuals in the context of the construction components, enabling them to understand dangerous situations regardless of language barriers. This changes their attitude to the change process. It's a small step towards greater construction safety; a big one when one considers that every tool helps to save lives. Surveys show that the accident rate in construction is still twice as high on average compared with other sectors. "Helmets and sturdy shoes are not enough. Safety must be seen in a comprehensive way and also include the organisation in a broader sense. More safety on construction sites is good for everyone involved: clients, contractors and workers," says Weißengruber. Because safe construction sites also mean economical construction sites and this pays off in any case.

Safety as added value

Why do so many decision-makers find it difficult to make this connection? Sonnberger explains it by saying that safety is an added value that is not necessarily reflected in the price. Until you change your habits, you may not be aware of how much they are costing you. The benefits of increased preventive measures are not visible to every decision-maker, who may also be far from the site where they are implemented. "Occupational safety is a management issue", says Sonnberger. At PORR, it is a direct responsibility of the Board of Directors. They know from their own experience that having a safety concept is less expensive than having no safety concept at all. The question is not whether you can afford the extra cost. The question is whether you can afford not to invest.Safety pays

Sonnberger talks about hard economic facts. Many companies link their decision to work with another company based on that company's accident figures. In an industry where profit margins of one to three percent are standard, it is easy to work out the turnover needed to offset the money lost due to accidents at work.1 Studies show that every euro invested in safety coordination leads to a return on prevention of 2.2 euros. It is also true that the foundations for around two thirds of all construction accidents are laid before construction is scheduled to begin – during the planning and organisation phase. Weißengruber calculates that up to around 18 percent more turnover could be generated if quality defects and accident costs can be minimised to zero. Absolute safety does not exist. It can only improve when we challenge assumptions about costs, time pressure or attitudes such as "That's how we've always done things".Creatures of habit live dangerously

"Humans are creatures of habit", says Weißengruber. Of course, he is pleased to see awareness-raising initiatives such as World Day for Safety and Health at Work raise. But safety is for more than just one day. Once new safety standards have been defined, they "only" need to be adopted as a new habit. He continues to provide webinars and training courses for Doka, and his team will be pushing for improved components and system solutions, accompanying in-house safety coordination and acting as an intermediary for the needs of companies and their construction workers. And he ensures that Doka components and systems are safe when they come onto the market and can also be used and operated safely.All to ensure genuine occupational safety.

1Every single occupational accident costs the company in which it occurs an average of 2,300 euros, (calculations by the General Accident Insurance Institution). On average, each accident at work costs the economy about 12,500 euros. https://www.arbeitsinspektion.gv.at/Uebergreifendes/Arbeitsunfaelle/Arbeitsunfaelle.html, Download 27.04.2021

Safety@Doka:

Doka safety systems are applied to every project phase. Safety is included in planning right from the start, coordinated with the formwork technology systems, and geared towards greater improvements in productivity and quality. Working platforms, including side protection and opposing guard rails are used for concreting. During high-wall formwork, intermediate platforms including side protection provide a safe and efficient solution. Safe ascent to the concreting level is particularly important for column formwork. Doka meets these requirements with practical safety solutions.Further information:

https://www.doka.com/uk/solutions/safety-with-doka

https://www.doka.com/uk/solutions/safety-systems

Stay in the loop and subscribe to our Press Newsletter!

To the registration formDo you have any questions on the article? Get in touch with us!