Framed formwork Framax Xlife

A wall formwork system sets new standards

Framax Xlife is the wall form system that uses only a very few different panel formats to achieve a consistent 6" (15 cm) increment-grid, no matter whether the panels are stood upright or on their sides. All the connectors and accessories fit seamlessly into this grid – making for fast forming-times and high efficiency.

Framax Xlife speeds up progress on your site with its

- small number of easy-to handle component parts

- quick lightweight clamp - only a hammer is required for assembly

- versatile tie solutions, taper ties, she bolts or thru-rods with tubes

- gang ability to fly entire pre-assembled units with one pick into place

- fast assembly that is consistently over 100 sq. ft. per man-hour

Highly economical thanks to

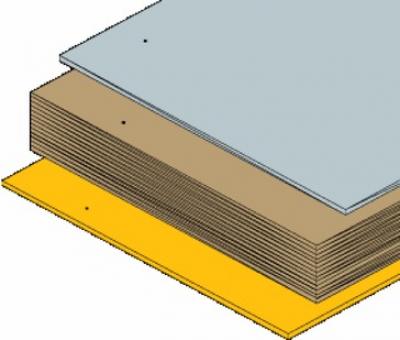

- 7/8 thick Xlife plywood that provides a consistent finish

- 7/8 thick Xlife plywood that is sealed in the frame with hot caulking and attached with screws from the back

Save time in the details thanks to

- Imperial dimensioned corner panels so there is no need to convert from inches to millimeters to form the details

- Stripping corners that allow for relief in a core at one location

- Universal panels for up to 42” columns at 1880 psf

- Hinged universal pilaster forms for fast stripping of gangs between pilasters

- Steel filler panels to eliminate wood fillers

The accident risk is reduced, and legally compliant working conditions are ensured, by having

- six safety tie off handle connections that are built into every panel and meet OSHA requirements.

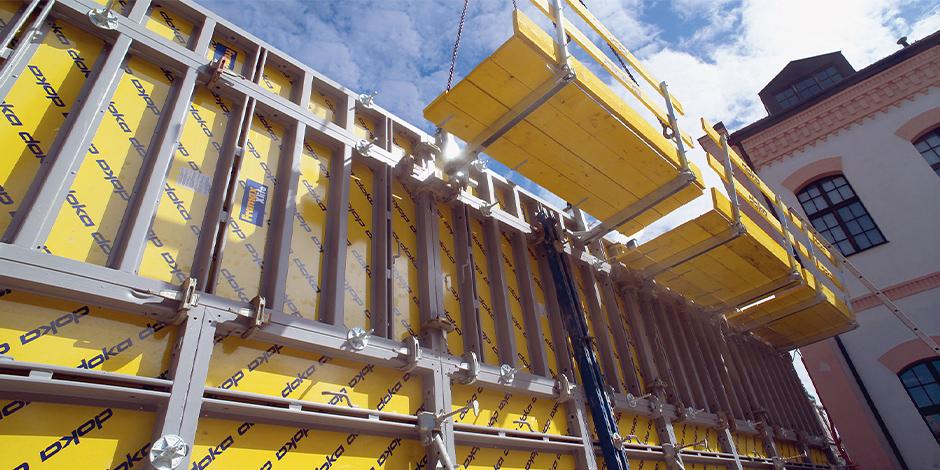

The large gang forms and wide tie spacing reduce the forming times for large areas to a minimum.

Experience this system in AR

The DokaAR App America allows users to view Doka Formwork in Augmented Reality.

Feature

Interview: Contractor’s Success with framed fromwork Framax Xlife

“We have been able to reduce our form and strip costs during projects, which also helps us be more competitive at bid time.”, Jason Barkhimer and Josh Mimna of CJ Mahan Construction Company.

30 years Framax Framed Formwork!

Doka celebrates how Framax Xlife wall form system boosts efficiency in every day practice.

About Wall formwork Framax Xlife

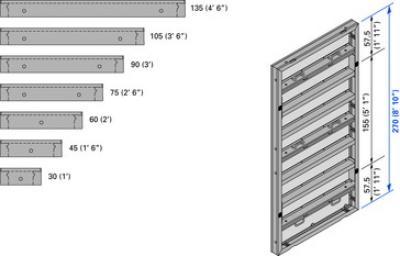

Framax Xlife wall form panels

- Modular and symmetrical panels ensure the best possible utilization of formwork.

- Only 7 panel widths in 6" increments simplifies planning, forming and logistics on the construction site.

- Reinforced holes in the panel frames allow for strong structural connections for bulkhead forming, dependable solutions for corners and column formwork.

- Hot-dipped galvanized and powder coated steel frames eliminate rust and greatly reduce maintenance costs.

Universal panels

The special pattern of holes makes these panels ideal for the economical forming of outside corners, wall connections, bulkheads and columns.

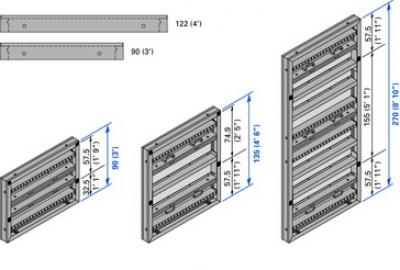

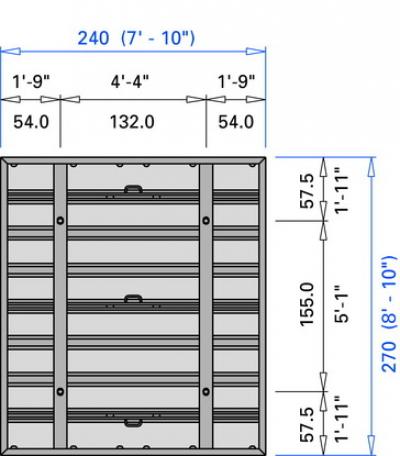

Framax Xlife large panel 240 x 270

- For large gang form units or for use with support frames, fewer connectors.

- The panel can be used upright and facing each other.

- The large panel is ideal when less joints are desired.

Framax Xlife panel

Wall formwork Framax Xlife with the innovative Xlife facing takes the number of reuses way up and pushes follow-up costs way down.

Wall form for outstanding concrete surfaces

The special surface of the Framax Xlife panels produces an excellent concrete finish, not just the first time, but again and again and again.

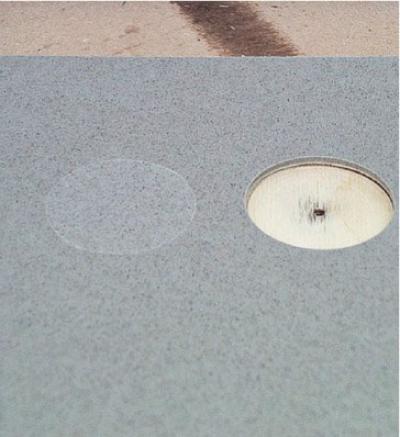

No fracturing of the surface when nails pierce the panel face

Nailing through the panel does not impair the clean face of the concrete. The surface of the wall form panel does not fracture and chip where the nails

Pierce it, so there are no ugly marks in the concrete.

Straight comparison shows that Wall formwork Framax Xlife nails much better than conventional formwork panels.

Easy to clean and recondition

The surface of the panel is extremely dense and smooth, so dried concrete scrapes off easily. The panels can even be cleaned with high pressure washers.

The damaged area is routed out with a special router bit and a plastic patch applied for a seamless finish.

Shaft formwork

Doka stripping corners are designed specifically for shafts.

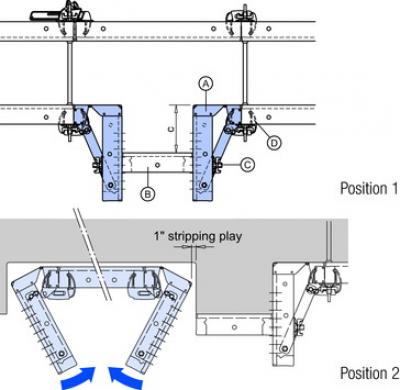

Pilasters

The pilaster panels make quick work of forming pilasters. Pilasters up to 18", in 2" increments and 24" when used with outside corners.

Position 1: Locked at right angles with quick pins for pouring.

Position 2: Folded flat for stripping and resetting.

A: Pilaster panel

B: Framax Xlife panel

C: Universal fixing bolt + super-plate 15.0

D: Quick acting clamp RU

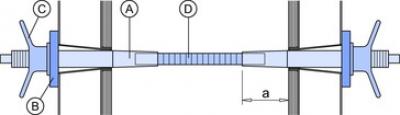

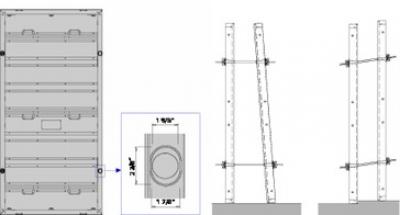

She-bolt system 1 1'/2"

A: She-bolt 1 1/2"

B: Anchor plate 1 1/2"

C: Wing nut 1 1/2"

D: Coil rod 1"

Permitted capacity allowing a 2:1 factor of safety against failure: 37,500 lbs (166kN)

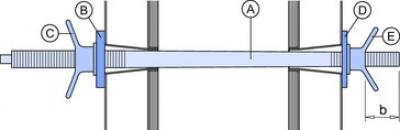

Taper-tie system 1 1/2"- 1 1'/4"

A: Taper tie 1 1/2" to 1 1/4"

B: anchor plate 1 1/2"

C: Wing nut 1 1/2"

D: Anchor plate 1 1/4"

E: Wing nut 1 1/4"

Permitted capacity allowing a 2:1 factor of safety against failure: 50,000 lbs (222kN)

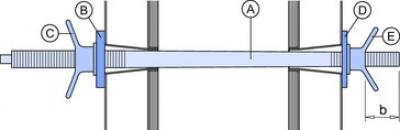

The Doka form-tie system 20.0

A: Tie-rod 20.0mm

B. Super-plate 20.0 B

C: Plastic tube 26mm

D: Framax S universal cone 1"

Permitted capacity, allowing a 2:1 facotr of safety: 38,000 lbs (169 kN)

The 135 x 270 Framax Xlife panels provide a tie spacing of 20 sq. ft. per tie. This means up to 20% fewer ties and correspondingly shorter forming times with this wall form. Labor costs for stripping and finishing of tie holes are also reduced.

Fillers

Steel and timber fillers make details a snap. The multi-function clamp has an adjustment range up to 6" (15 cm), which matches exactly the steps in panel widths. In many instances, a single filler per wall is all that is necessary.

Universal Panel SCC

The universal panel SCC permits self-compacting concrete (SCC) to be pumped into the formwork from below: Self-compacting concrete (SCC) reduces air content by itself and finds its own level. Ideal for complex geometries and very highly reinforced structural elements. No manual compacting is necessary. The universal panel SCC has a special adapter with a gate for connecting to concrete pumps.

- Perfect compaction even for thin, high and heavily reinforced walls.

- Walls are easily poured between floors.

- Can be used in the wall or bulkhead forms.

Framax Xlife Column Formwork

The 90 cm and 122 cm wide Framax Xlife universal panels are ideal for forming changing column cross-sections in 2" increments - without extra column formwork on the construction site.

- Accommodate column cross-sections of up to 42" in 2" increments.

- Are ideal for corners and bulkheads - for optimum utilization of the wall formwork.

- Reduce quantities on site and costs for rental, because they are universally adaptable.

- Can be lifted complete with the column formwork platform.

Circular Formwork with Framax Xlife

The fast way to form chorded circular walls

- With the Framax Circular forming plates and Framax Xlife formwork panels, radius walls can be formed effortlessly.

- Reduce costs and form circular walls efficiently by using existing Framax Xlife panels and all accessories such as panel struts and pouring platforms from the Framax Xlife product line.

- This makes circular forming of curved concrete walls with Framax circular forming plates economical and fast.

How to use Wall Formwork Framax Xlife

Integrated waling system

Connecting rails over the entire width of the panels ensure fast installation of accessories such as panel struts, universal waling and walkway brackets - quick as a flash at any location along the integrated waling system.

Connectors

Joining the panels takes a single blow with the hammer - for fast assembly of the wall form without additional tools. Only two lightweight clamps are required for joining two 270 high panels. The RU clamps have no fixed position. Adjacent panels can be at different elevations because of the frame profile.

The safe way to pour concrete

Wide working platforms make work faster and safer. Framax Xlife pouring platforms fold out quickly and drop into position ready to start pouring.

Safety tie off handles

- To facilitate work on the formwork

- To attach a safety harness

- Meets the OSHA requirements