Press Contact

Impressions

Floors, walls and columns sourced from Doka

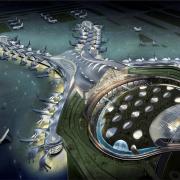

The colossal piers demand the expertise and know-how of Doka. They are designed to accommodate up to 65 aircraft and able to handle planes as large as the A-380 Airbus megaliner. Doka's Abu Dhabi branch won the customer over with an economical and time-saving formwork solution tailored to the unusual shape and the tight 15-month schedule for cast-in-place concrete construction.The Load-bearing tower Staxo 40 scores big when it comes to forming the floors that require a total of 11,000 m2 Doka floor formwork. The lightweight shoring system stands out for its exceptional ease of handling, quick assembly and maximum adaptability. The solution for supporting walls and columns is provided in form of the Large-area formwork Top 50. The pre-assembled formwork system meets all architectural requirements with respect to form, size and form-tie pattern. In addition 6,400 m2 Framed formwork Frami Xlife are in use.

Doka project management on site

A Doka project coordinator ensures a smooth workflow throughout all stages of the project. A team of technicians and a formwork instructor are on-site to instruct the crew in using the formwork safely and effectively. Crucial ingredients for a smooth workflow and successful project are daily coordination of formwork delivery to the site and on-site distribution of materials. In addition, the team at the Doka branch are also forging ahead intensely on the project. Thus far the Engineering Department completed 500 project drawings."In the past, I collaborated with Doka on several projects similar to the Abu Dhabi Midfield Terminal Building. Doka is a reliable partner for this project. With its know-how and technical solutions, the team significantly contributed to us achieving our milestones. Doka practitioners provide support directly on site; even materials required on short notice are delivered quickly", so Huseyin Misirlioglu, Senior TAV Project Manager on collaborating with Doka.

The Midfield Terminal Complex is not the only project in the aviation sector where Doka's expertise is sought. Construction of the international airports in Muscat and Salalah in Oman, the King Abdulaziz International Airport in Jeddah, Saudi Arabia, or the New Doha International Airport in Qatar are additional projects where Doka demonstrated its skills in developing solutions.

Do you have any questions on the article? Get in touch with us!