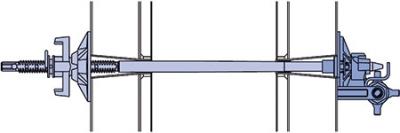

Monotec tying system

The single-side-operable tie-rod system for Framax Xlife retrofitting

Allows form-tie points to be prepared quickly and reliably by just one person. This ergonomically comfortable option for manipulating the ties from just one side of the formwork saves time, and thus shortens the forming-times.

Single-sided tying technology made easy:

- sealing plugs fit effortlessly into the tie-holes of the holding formwork

- tying through the frame needs fewer separate parts, as form-tie nuts are integrated in the panel connectors

- form-tie nuts are easy to pin to the inside tie-points of extra-large panels

- only two taper-ties for wall thicknesses of 15 to 35 cm

Reduced labour requirement, as

- form-tie points can be prepared reliably by just one person

- there is no need to cut and fit jacket tubes and cones

- it is no longer necessary to climb into shaft formwork, provided the Stripping corner I is used

Save on equipment and manhours:

- tie-length is easy to fix, with pins, in 1 cm increments

- form-ties can be tightened and loosened quickly with the Monotec ratchet

- only one size of plug fits all tie-points in the concrete (cuts search-times)

- fewer intermediate platforms needed on tall holding formworks

- high-grade hard chrome plating makes the form-ties easy to remove

Single-side-operable Monotec form-tying system for retrofitting to Framed formwork Framax Xlife.

Only two different types of conical Monotec ties are needed for economically forming wall thicknesses of between 15 cm and 35 cm.