Forming speed in a

Panel floor formwork Dokadek 30

Slab formwork at its most evolved.

Dokadek 30 is a beam-less, hand-set formwork system designed as a lightweight strip galvanized and cathodic dip painted steel frame faced with a wood/plastic-composite sheet.

Speed

Quick to put up quick to take down.

Fast forming of large areas thanks to 32 sq.ft. Dokadek panels

as there are far fewer parts to be shifted. This greatly speeds up the forming operations. The entire system has only three different components: panels, heads and props.

Fast formwork removal is a critical success factor

because this operation takes up around 33 % of the total forming time. With Dokadek 30, the panels are stripped out without any time consuming overhead work. The DekDrive then lets you shift up to 130 sq.ft. of Dokadek 30 at a time.

Minimal crane-time needed during formwork set-up

which means that work can move ahead rapidly, independently and without interruption. There are no unproductive downtimes spent waiting for the crane, as the equipment does not need to be lifted onto the floor-slab formwork. In other words, the crane is no longer a ‘choke-point’ during formwork set-up. It is only needed occasionally, to help with closing infill and intermediate zones.

Safety

Productivity on safe ground.

Fast, safe erection sequence, working from floor-level

The rectangular shape of the Dokadek panels also makes it easy to form higher slabs from the safety of floor-level work: Simply hold the panels by the ergonomically shaped grip-holes, lift them and hook them into the Dokadek heads, then raise the free end with the Dokadek assembling tool.

Integral anti-liftout guard

The Dokadek heads have a built-in anti-liftout guard which prevents panels accidentally falling off and makes extra precautions (such as wind bracing) unnecessary. This saves time and money.

Railings from Doka edge protection system XP.

Dokadek 30 is fully compatible with the Doka edge protection system XP. This brings an added dimension of safety.

Simplicity

Easy to explain, easy to use.

Short introductory training time

Because Dokadek 30 has so few separate parts, and such a straightforward erection sequence, even semi-skilled laborers can soon use it correctly. Right from the word ‘go’.

Tackling infill zones is easy

With the suspension clamp, infill zones can be formed quickly and easily, as Dokadek 30 merges here seamlessly with Dokaflex. In fact, Dokadek 30 combines perfectly with all other slab systems from Doka.

Pre-defined erection sequence.

The clearly defined erection sequence prevents the crew from attempting dangerous improvisations, and ensures a consistently high safety level – even when semi-skilled labour is deployed. Because of the number of props and how they are arranged, with Dokadek 30 there is no need to dimension the system in advance. Without additional measures a slab thickness of up to 12.5" is possible.

Fewer parts per sq.ft. of slab formwork.

There are only two different sizes of panel, which simplifies logistics on the site and means there is no time wasted searching for the right parts. The forming operations themselves go much more smoothly, too.

Great concrete results,time after time

thanks to the tried-and-tested Xlife sheet.

Xlife sheet

The innovative coating made of glass fibre reinforced plastic ensures even greater resistance to scratching and mechanical damage. This means positive impressions on the concrete and rework costs are cut even further.

- Rework expenses cut even further

due to fewer positive impressions on the concrete thanks to increased resistance to scratching and mechanical damage such as from vibrator - Lowest cost per use and fewer-form ply replacements

thanks to even further increased lifespan - No unsightly staining

on concrete as it is the case with phenol resin sheets - Easy, fast and non-destructive cleaning

that can also be performed with a pressure washer

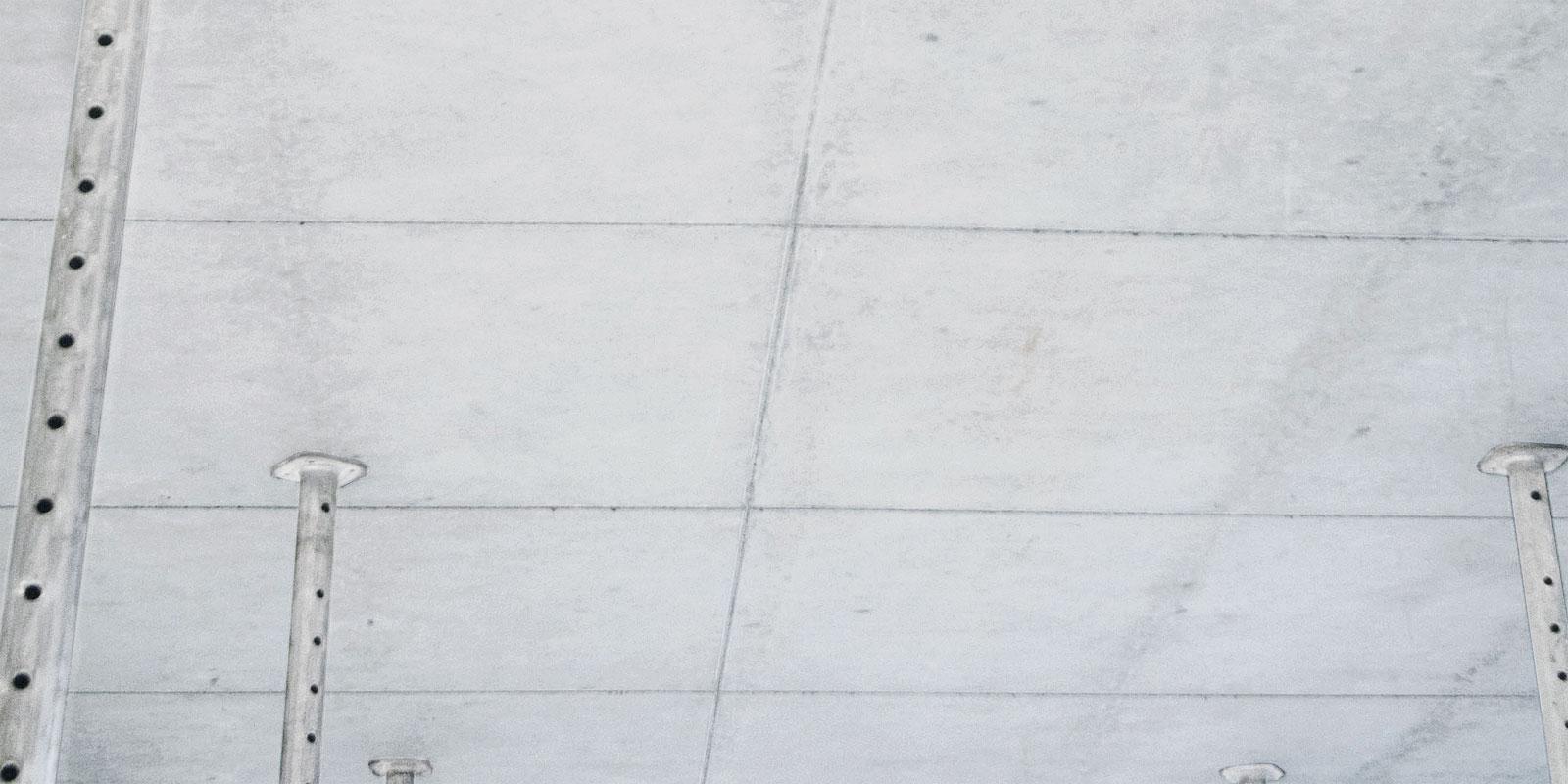

Final results

The final results are clear to see: a small number of joints, all of them neat and tidy as well as a uniform concrete finish.

One System, three working methods

How you use Dokadek 30 is up to you, depending on your requirements.

Method 1

Dokadek 30

without drop-head

Dokadek 30 standard system

Method 1 Concremote

Dokadek 30

without drop-head, with Concremote

Earlier stripping with the Dokadek 30 standard system, based on actual concrete compressive strength with Concremote.

Method 2

Dokadek 30

with drop-head

Traditional early stripping with drop-head

Decision support:

You define the working method

The forming method chosen will depend on e.g.

- the required cycle times

- the stipulations of the structural designer

- the weather during the shell-construction period

- the concrete technology

Every construction task needs individualised solutions. The Doka Formwork Experts will be pleased to advise you.

Doka floor-slab systems:

It all fits together

Doka floor-slab systems are versatile and can be adapted to handle widely differing construction tasks. No matter whether the areas of slab to be formed are large or small, straightforward or complex: with Doka, you’ll always be working right, and working safe.

Dokadek 30 is compatible with all other Doka floor-slab systems. As necessitated by the requirements, the most suitable floor system can be used in each case – or a combination of different systems.

A

Dokadek 30 and timber-beam floor formwork

The new equipment line-up for high speed on large areas and fast adaptation in infill zones.

B

Dokadek 30 and tableforms

The professional solution for combining efficiency on large areas and around edges.

C

Tableforms and timber-beam floor formwork systems

The proven combination for high forming rates and maximum flexibility.

Would you like to have further information on Dokadek 30?

Get in touch with us!